Skills Ontario 2023 Hockey Robot

A custom-built hockey robot for the Skills Ontario Robotics Competition, designed and assembled from scratch without a kit.

Technologies Used

About This Project

Overview

Every year, the Skills Ontario Competition brings together Ontario's top students to showcase their technical prowess in a series of challenging events. In 2023, our team took on the intense two-and-a-half-day robotics challenge with an ambitious approach that set us apart from the start. Embracing our 'No Kit Needed' philosophy, we decided to forgo the convenience of pre-made VEX kits and instead built our hockey robot entirely from scratch, pushing the boundaries of what we could accomplish with raw materials and determination.

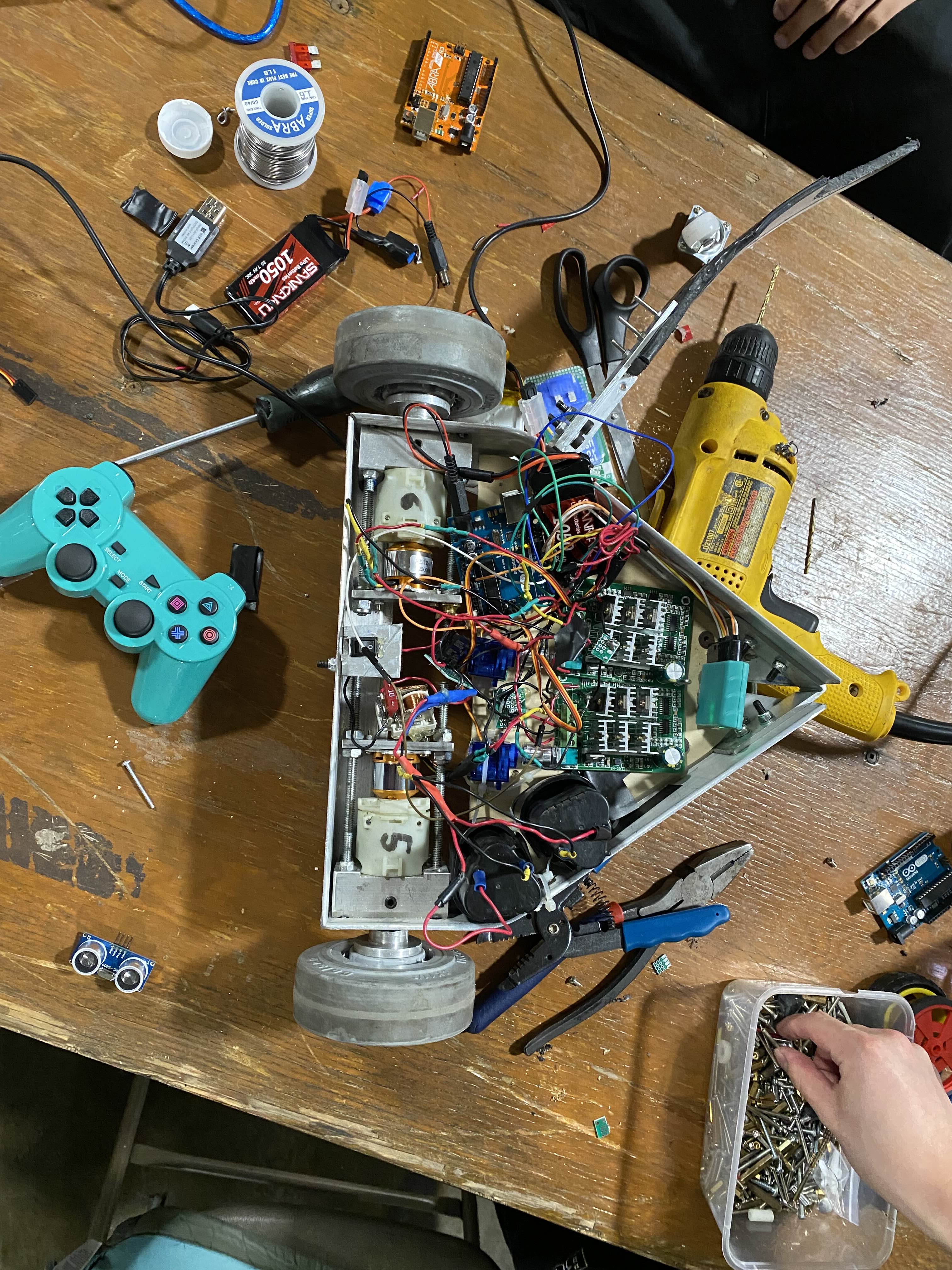

Building from the Ground Up

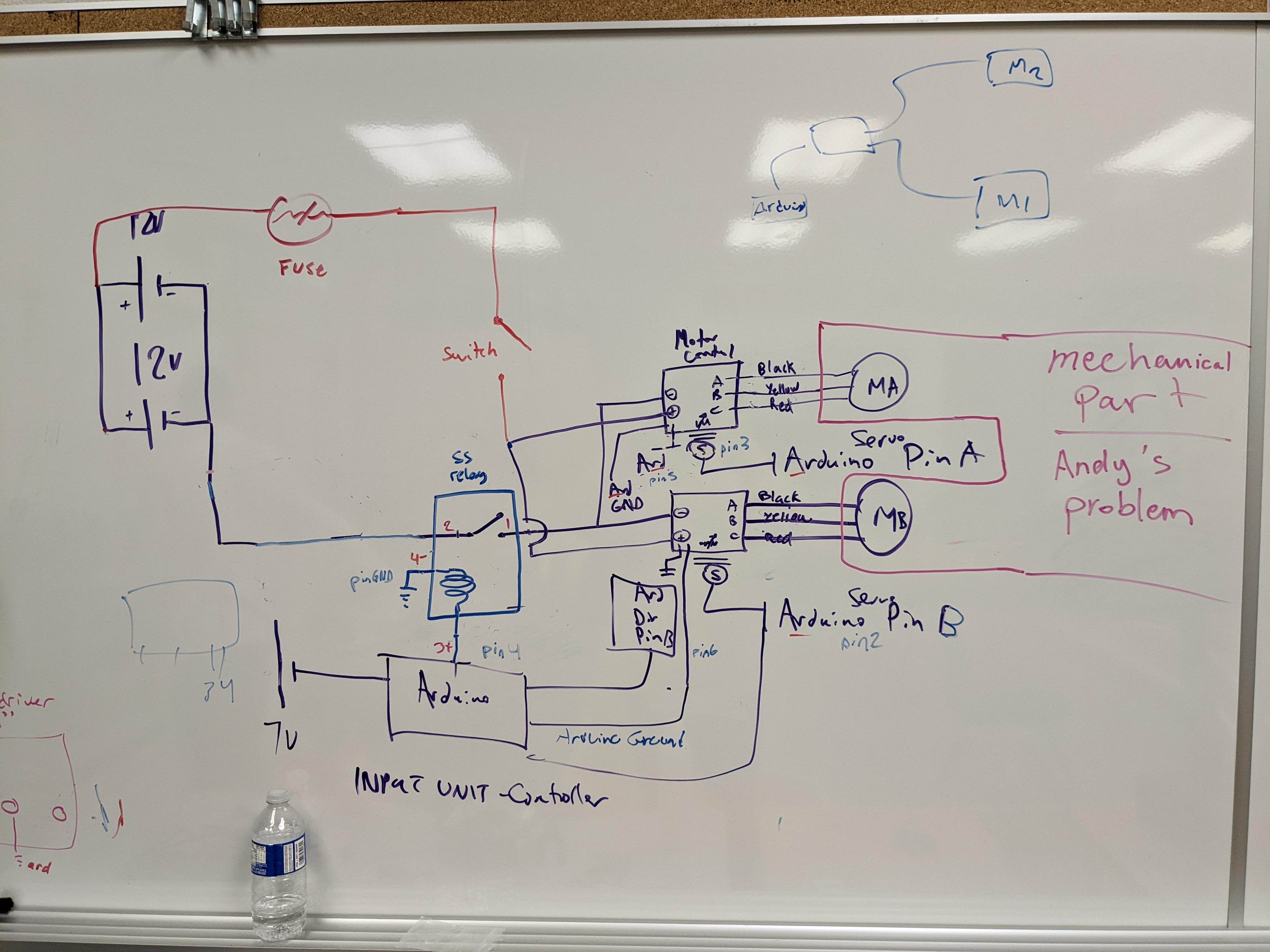

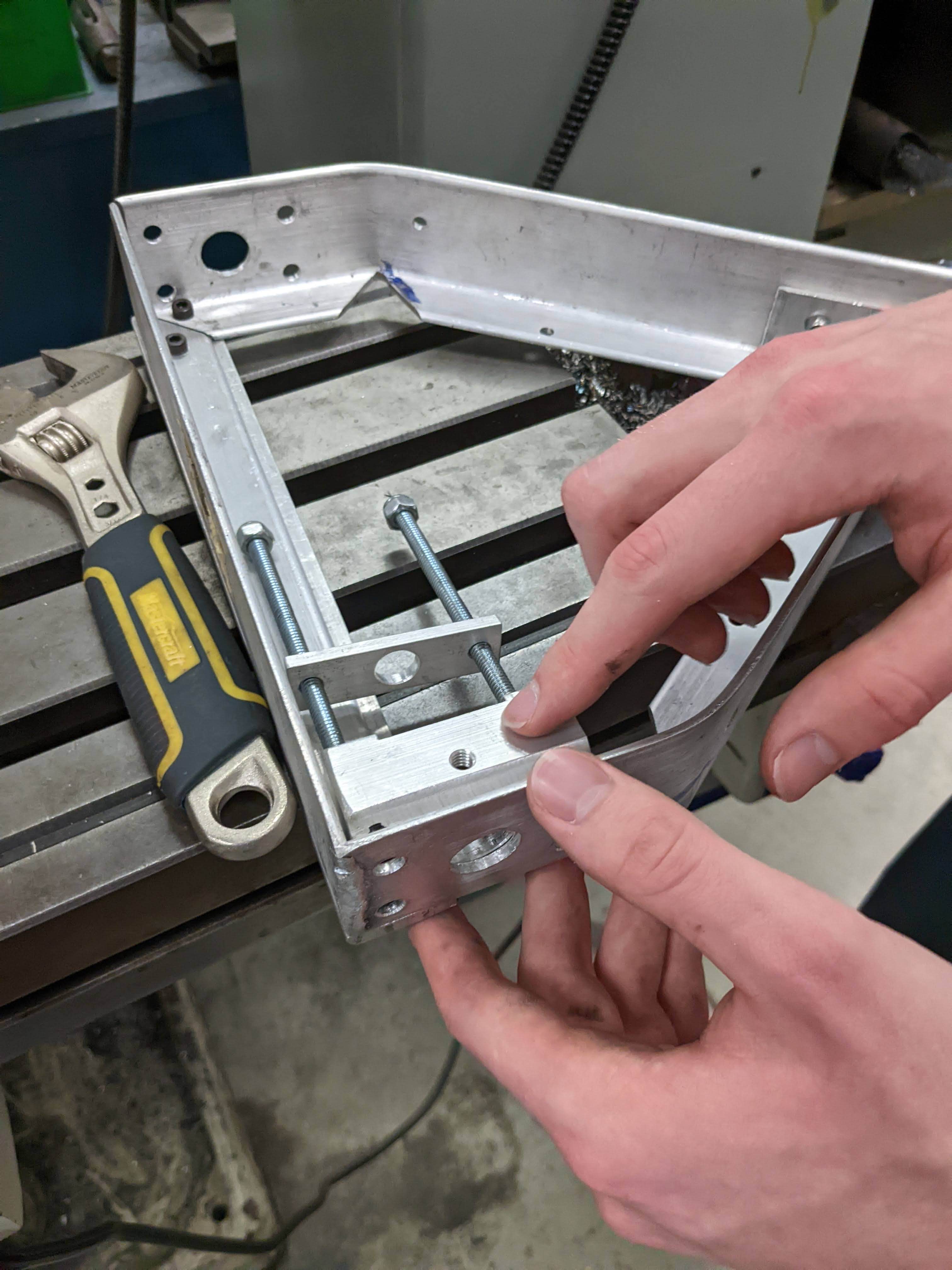

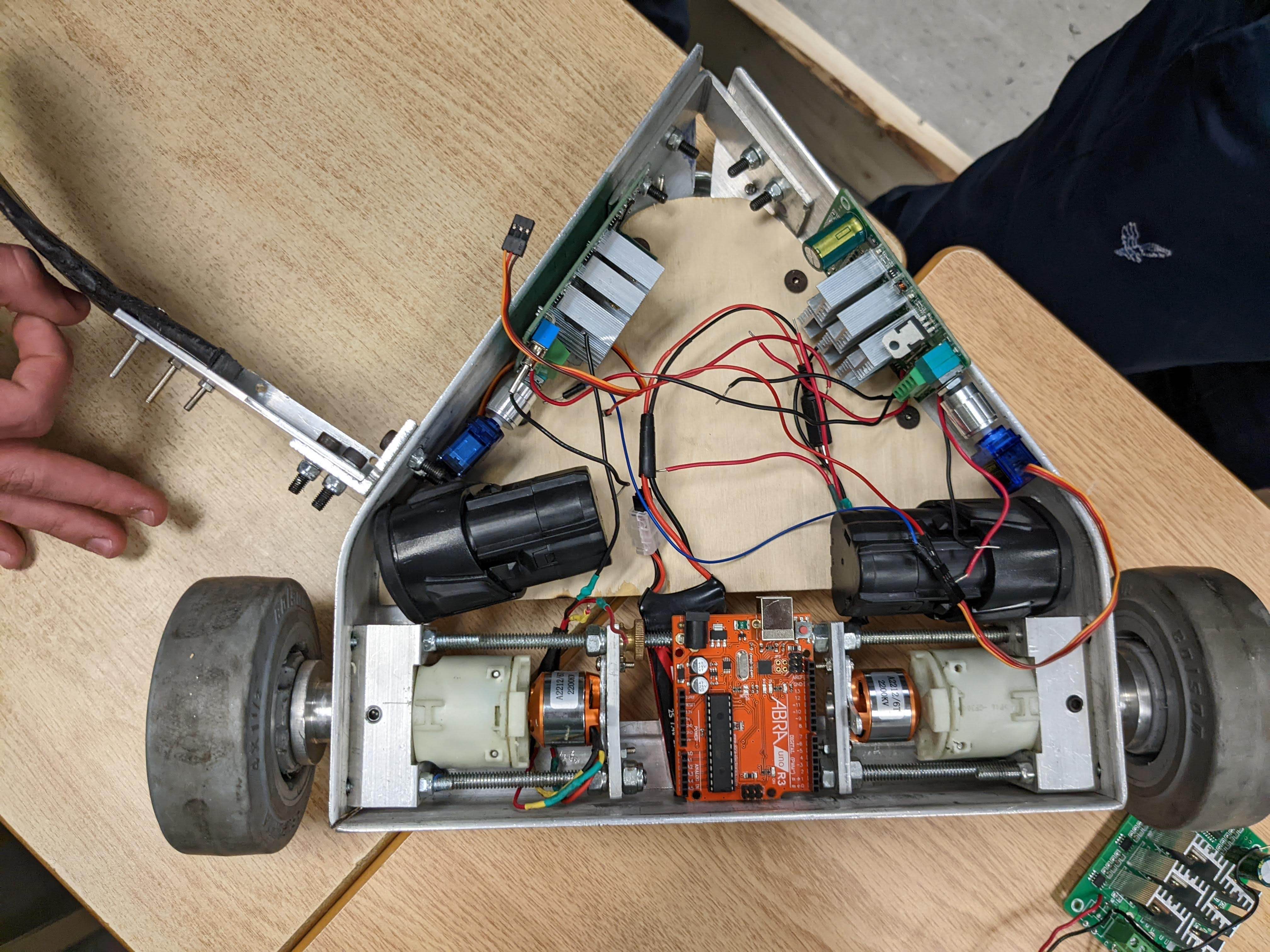

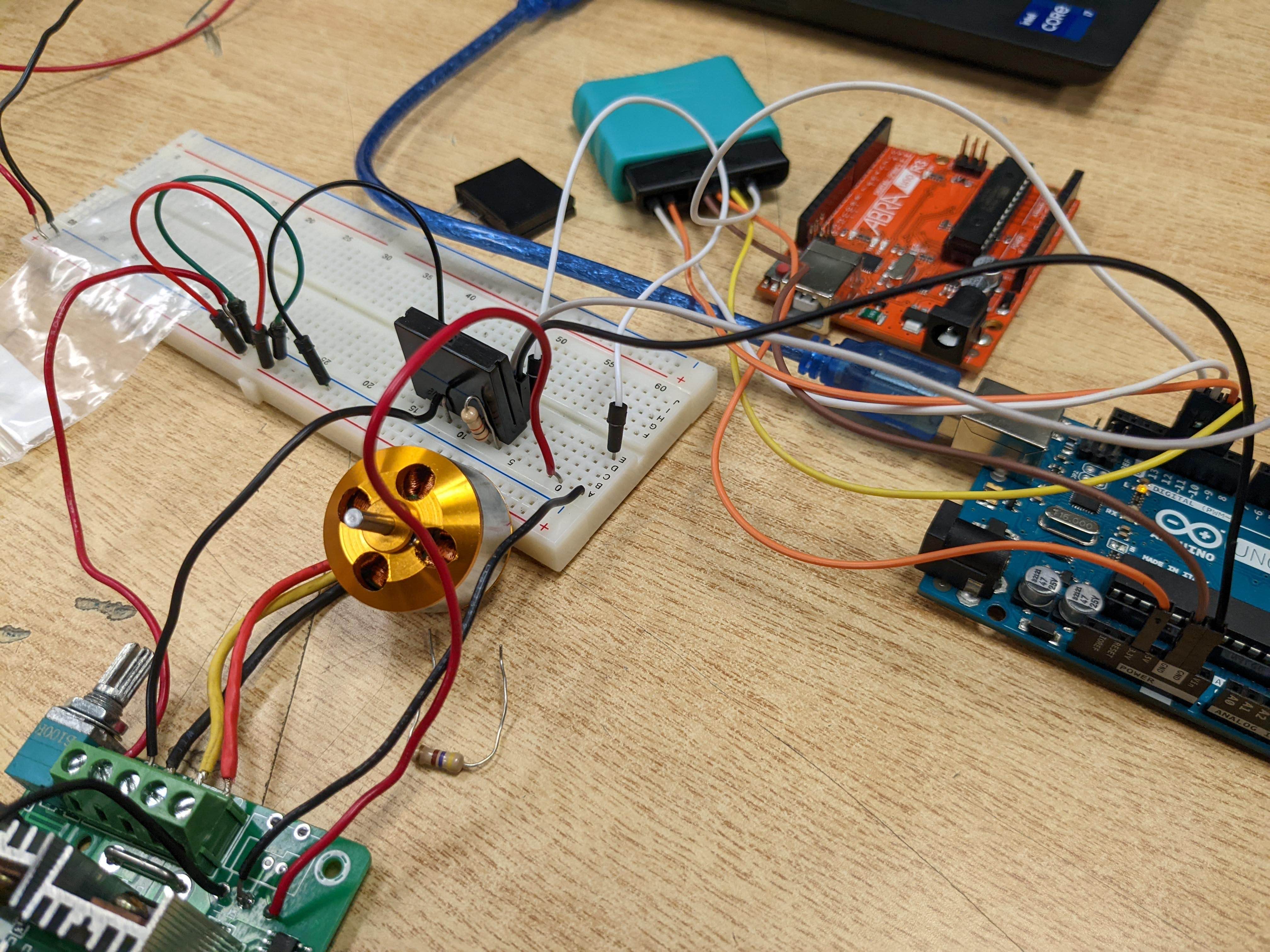

With our 'No Kit Needed' philosophy as our guiding principle, we dove headfirst into the fabrication process. Starting with raw aluminum, we carefully crafted a sturdy chassis that would serve as the foundation for our robot. Every mechanical component was designed and built by hand, from the frame that housed our electronics to the intricate parts that would make our machine move. We sourced powerful 3-phase motors and drill batteries, then meticulously assembled and soldered all the electronics ourselves. The control system was equally custom-built—we designed wireless communication using Bluetooth PS2 controllers paired with Arduino boards, drawing every circuit diagram by hand and writing code for each module from the ground up. This hands-on approach not only challenged us technically but also gave us complete ownership over every aspect of our creation.

Electronics & Testing

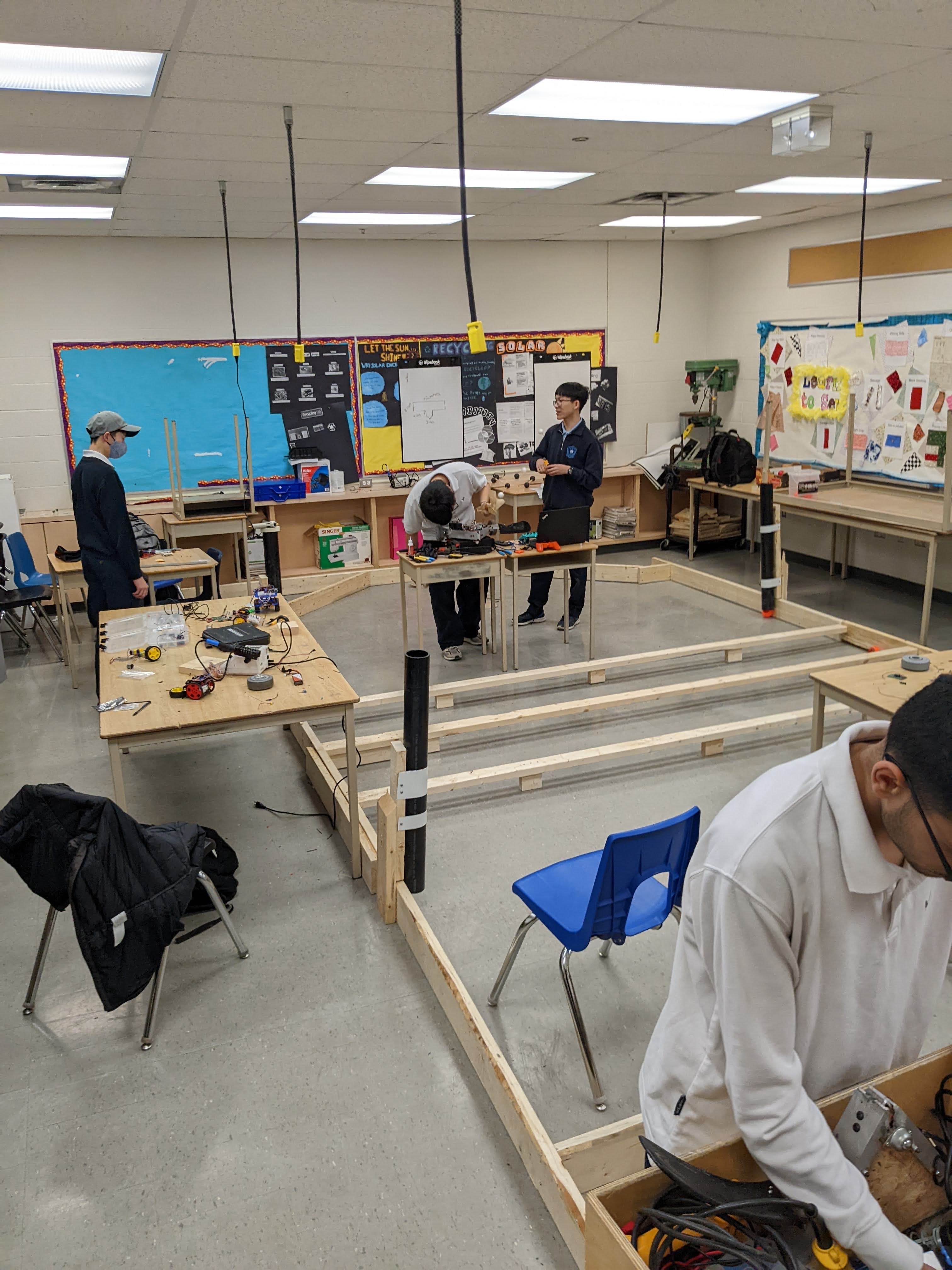

Once our custom electronics were assembled, we turned our attention to rigorous testing to ensure everything would perform reliably under competition conditions. We spent countless hours in the classroom, running our robot through various scenarios to identify and resolve any potential issues. Each test revealed something new about our creation, and we iteratively refined our systems to build confidence in our robot's capabilities. This thorough testing phase was crucial, as it not only validated our engineering decisions but also prepared us mentally for the unpredictability of competition day.

Facing Challenges

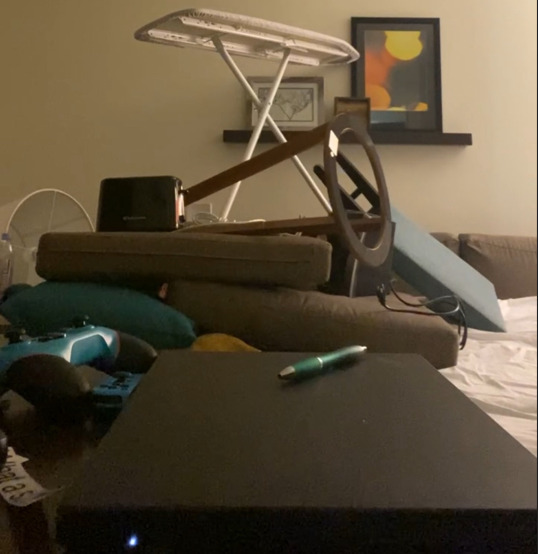

Building a robot from scratch within the constraints of a student schedule presented its own set of challenges. With only limited after-school hours available, we had to be incredibly efficient with our time, sometimes working late into the evenings to meet our ambitious goals. The real test of our resolve came just before competition when a critical malfunction threatened to derail everything. We found ourselves in a Toronto hotel room late at night, frantically soldering connections, gluing components, and debugging code in a makeshift workspace. Through sheer determination and teamwork, we got our robot operational again, arriving at the competition with a fully functional machine that reflected our unyielding commitment to the 'No Kit Needed' philosophy.

Competition & Teamwork

Competition day finally arrived, and we took to the field against teams using sophisticated VEX kits. Our from-scratch robot held its own admirably, performing respectably in a field of highly capable machines and earning recognition for our innovative approach. Beyond the technical challenges, the event became a memorable team-building experience. We explored Toronto's vibrant streets, sampling local cuisine and creating lasting memories together. The highlight of our trip was undoubtedly the legendary hotel prank that had us all laughing late into the night, reminding us that while engineering requires focus and precision, the bonds we form along the way are equally important.

Custom Patches

As a lasting symbol of our journey, we designed custom patches that captured the essence of our project. Each patch proudly featured our robot at its center, surrounded by meaningful elements that told our story—the orange game ball we competed for, a 15-tooth gear representing May 1st (our competition date), a crown symbolizing our achievement, and our school colors uniting us as a team. Above it all stood our motto, 'No Kit Needed,' a reminder of the bold philosophy that drove us to build something truly unique from the ground up. These patches became more than just memorabilia; they represented the pride we felt in our accomplishment and the lessons we learned along the way.

My Role

As one of the four core team members on this project, I took on the responsibility of helping our team through every aspect of the robot's development. I worked on the mechanical, electrical, and software integration, ensuring that all components worked together seamlessly. Under intense time pressure, we designed robust circuits, carefully integrated the motors, and wrote the control code that brought our vision to life. Beyond the technical achievements, I helped foster an environment where hands-on learning and creative problem-solving flourished. This role taught me the importance of balancing technical expertise with team coordination, and it reinforced my passion for projects that push boundaries and create lasting memories.